E400UV roll to roll and flatbed printer is a new printing machine which combined flatbed printer with

inkjet printer in one machine, exquisite workmanship and stable production.

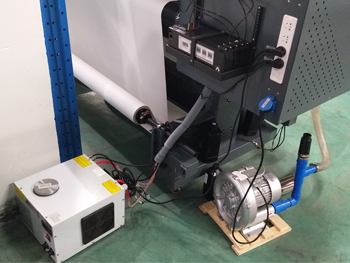

E400UV is equipped with the feeding and take up system for roll printing,and also comes with front and back extension

platform for plate printing. The conveyor feeding system can convey both rigid and flexible media accurately.

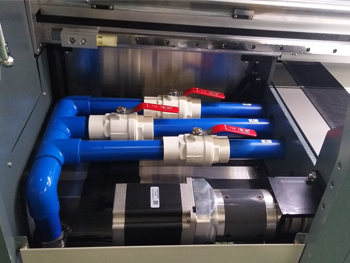

It can print roll and plate material at the same time. The vacuum system controls the whole printing platform

to remain media smooth without wave, and make true of “edge to edge” printing.

Features:

1.High precision hybrid printer , smooth and steady;

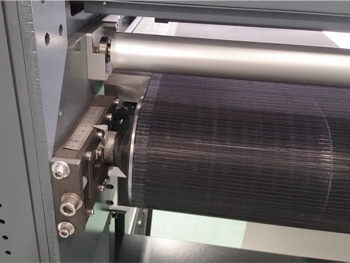

2.Auto-roller take up and feeding system,suit for volume production;

3.Steady and reliable,high speed printing without wrinkle or run deviation;

4.Conveyor belt feeding,whole roll material printing;

5.Intelligent adjustable subarea suction for different thickness materials;

Details:

1.Print both rolls and plate materials,efficiently solve the problem of printing rolls and plate materials in one machine,

it's mainly usedin advertising,photographic studio,decoration and other industries;

2.Full range of air-suction function,it is convenient for the transmission of rolls and plate materials.

3.Intelligent infrared heating, which can automatically shut down the heating system while the machine stop printing,

very safe and reliable.

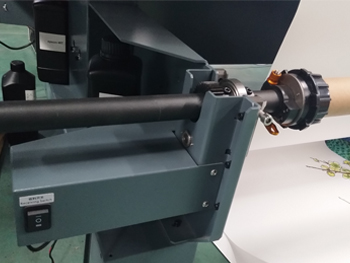

4.With advanced servo control system, ensure the accuracy of the printing position and consistency,

very long length material can be also transmitted smoothly.

5.Efficient on-line material drying system, fast drying the materials.

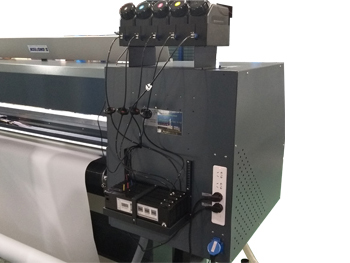

6.Perfect design of ink system, ensure the continuity and quality of printing.

7.High resolution and high speed to satisfy different customers with different orders, realizingthe rapid production of the batch,

varieties and more personalized.

8.Support a variety of image formats and software, such as JPG/TIFF/AI/EPS/PS.

9.High speed data processing and transmission.

10.Adopt professional RIP, enhance production efficiency greatly.

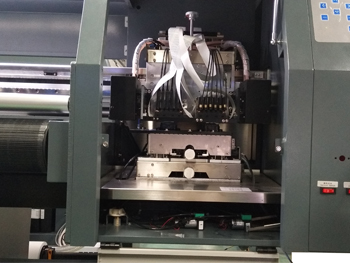

11.Adopt advanced band conveyor device and printhead adjustable device; It can adjust theheight of cleaning system

and carriage at the same time, it could fit all kinds of cloth thickness,Flat board material.

12.Max printing thickness is 30mm.

13.Standard tension rail take-up system,Auto take-up system.

14.Intelligent vertical location in the front and back.

15.Special anti-collision mechanism for carriage,lengthen the lifetime of printhead.

|

|

|

|

|

|

|

|

|

| Model |

E400 UV |

||

|

Max Print Width |

1830mm | ||

|

Print head |

I3200-U1 | ||

|

Number of Print head |

2, optional 4 | ||

|

Max Resolution |

1080dpi | ||

|

Max Printing Thickness |

30mm | ||

|

Color Mode |

Dual CMYK | ||

|

Output Speed

|

Number of print head |

2 heads |

4 heads |

| 6 Pass |

24 m2/h |

46m2/h | |

| 8 Pass |

18m2/h |

36m2/h | |

| Ink Type |

UV ink,optional Eco Solvent ink |

||

| Media adsorption system |

With |

||

| Language |

English |

||

| Software |

Maintop 6,optional Photoprint |

||

| Print head Cleaning |

Automatic |

||

| Heating system |

with |

||

| Power |

AC220v,50HZ/60HZ |

||

| Print Material |

Pvc, pp, soft materials, textiles, pvc board,hollow board, metal, wall paper, leather, glass, fabric, acrylic, etc. |

||

| Image format |

JPG/TIFF/AI/EPS/PS. |

||

| Machine Packing size /weight |

3350x1270x1550mm(LxWxH)/791KG |

||

| Warranty |

12 months Parts Warranty |

||